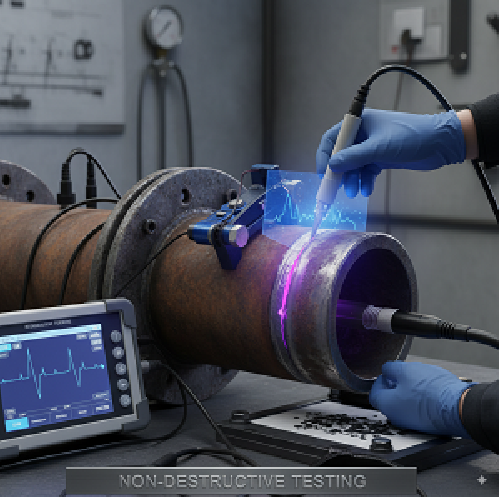

Non-Destructive Testing (NDT)

Ensuring Safety & Reliability Without Compromise

| Non-Destructive Testing (NDT) refers to a group of analysis techniques used to evaluate the properties of a material, component, or system without causing damage. Unlike destructive testing, which compromises the integrity of the tested item, NDT allows the item to remain in service after inspection. |

Key Objectives of GN NDT

• Detect Defects such as cracks, voids, corrosion, or misalignments

• Ensure safety and reliability of components in critical applications

• Maintain product integrity during and after testing

• Reduce costs by avoiding waste and preserving usable materials

• Support preventive maintenance and life-cycle management

• Comply with industry standards and regulations to meet quality and safety requirements

• Provide accurate and reliable data for engineering and quality control decisions

• Improve efficiency in manufacturing and inspection processes

Your Partner

Your Partner in Reliable GN NDT Services

"We provide advanced Non-Destructive Testing solutions to ensure safety, reliability, and efficiency across industries, helping you detect flaws without compromising quality."

Advanced Inspection Solutions That Preserve Integrity

Innovating Non-Destructive Testing for a Safer Tomorrow

🏭Services offered by GNNDT

Authority Approvals

Storm Power, as a DEWA approved contractor, will assist you in obtaining DEWA approval swiftly. We can help you acquire a no-objection certificate for the building or an electrical connection. For electrical systems, we also provide DEWA certification. As a well-known construction company in Dubai, we submit all of the necessary drawings to the authorities and obtain permission on behalf of our clients. Our own experienced designers and engineers will give the finest service and help. We want to stay on schedule and deliver on time.

- Dubai Municipality(DM)

- Dubai Civil Defence (DCD)

- Dubai Multy Commodities Centre Authority (DMCC)

- Dubai Silicon Oasis

- Solar Approval (Shams Dubai)

- Dubai Electricity & Water Authority

- Roads & Transport Authority (RTA)

- Trakhees, Nakheel, Emaar, DAFZA

Construction & Project Management Services

As a prominent Dewa approved contractor and construction company in Dubai, we listen carefully to what our clients require. We pay close attention to the needs of our clients and strive hard to make them a reality.

- Building construction

- Interior Designing

- Engineering Planning

- Fit Out Works

- Mechanical, Electrical & Plumbing

Frequently

Asked Questions

Ultrasonic Testing (UT) is a versatile non-destructive testing (NDT) method that uses high-frequency sound waves to inspect materials for internal flaws or to measure their thickness. It's a bit like a medical ultrasound, but for industrial components. It's a crucial tool for ensuring the safety and integrity of structures without causing any damage to them.

Radiographic Testing (RT) is a powerful method of non-destructive testing (NDT) that uses X-rays or gamma rays to inspect the internal integrity of materials and components without causing any damage. It works by passing radiation through an object and capturing the resulting "shadow image" on a special film or digital detector. Think of it like a medical X-ray for industrial parts, revealing hidden flaws like cracks, voids, or inclusions.

Magnetic Particle Testing (MPT), also known as Magnetic Particle Inspection (MPI), is a fast and reliable non-destructive testing (NDT) method. It's used to detect surface and near-surface flaws in ferromagnetic materials (materials that can be magnetized), such as iron, nickel, cobalt, and their alloys. MPT is a popular choice because it's sensitive, cost-effective, and provides immediate results.

Liquid Penetrant Testing (LPT), also known as dye penetrant inspection (DPI), is a widely used and cost-effective non-destructive testing (NDT) method. It's used to find surface-breaking defects, such as cracks, porosity, and leaks, in non-porous materials. LPT is based on the principle of capillary action, where a low-viscosity liquid (the penetrant) seeps into very small surface flaws.

Ultrasonic Thickness Measurement (UTG), also known as ultrasonic gauging, is a non-destructive testing (NDT) technique used to measure the thickness of a material. It works by sending high-frequency sound waves (ultrasound) into a material and measuring the time it takes for the waves to bounce back from the opposite surface. Based on the time of flight and the known velocity of sound in the material, the device calculates the thickness. This method is widely used in industrial settings to inspect pipelines, tanks, pressure vessels, and other structures for material loss due to corrosion or erosion.

Stress Relieving (SR) is a crucial heat treatment process in industrial solutions. It's not a "test" in the traditional sense, but a procedure that ensures the integrity and performance of a material. SR reduces internal residual stresses, which are often created during manufacturing processes like welding, machining, casting, or cold forming. If left untreated, these stresses can lead to problems like distortion, cracking, or premature failure of the component.

Positive Material Identification (PMI) is a non-destructive testing (NDT) method used to confirm the chemical composition of a metallic material. It's used to verify that the material being used in a component or system matches the required specifications.

Client I Have Worked for and There Logo